In the world of battery manufacturing, the precise and uniform application of electrode coatings is crucial to ensure the performance and reliability of batteries. One essential tool that plays a significant role in this process is the Wet Film Applicator.

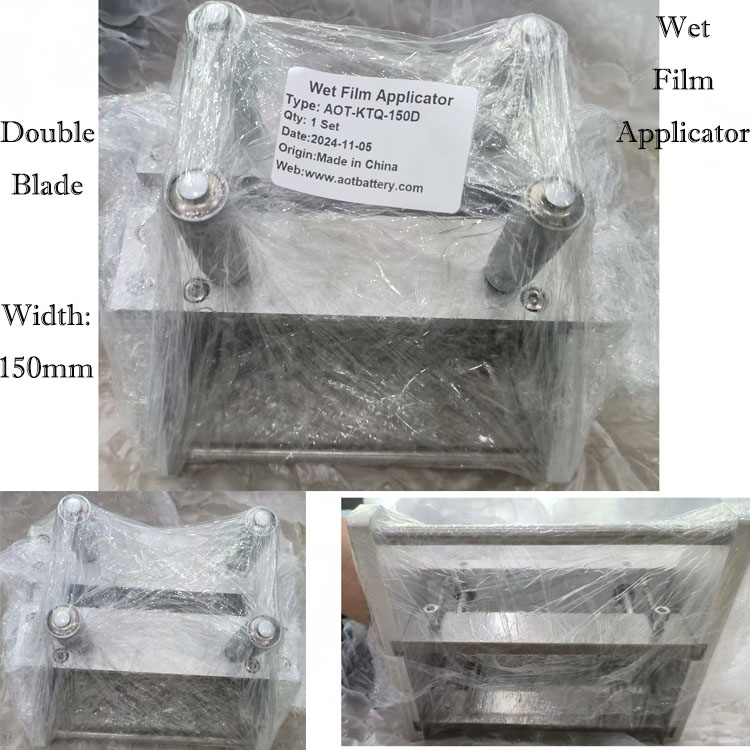

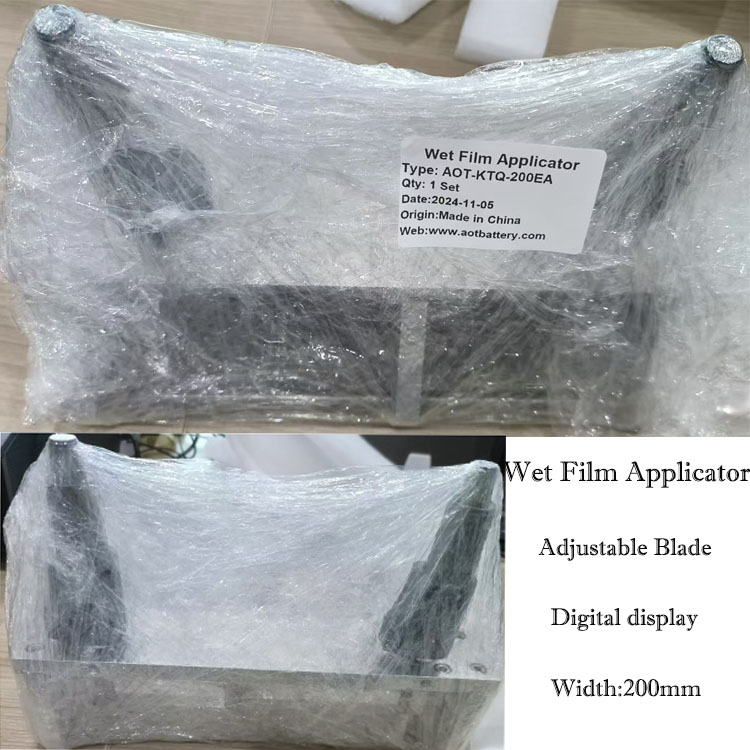

The Wet Film Applicator is a specialized device used for applying electrode coatings onto the current collector substrate. It consists of a flat, adjustable blade that evenly spreads the slurry onto the substrate, creating a thin and uniform wet film. This step is critical as it directly influences the thickness and quality of the electrode coating, which ultimately affects the battery's overall efficiency and capacity.

The Wet Film Applicator offers several advantages in the electrode coating process. Firstly, it allows for precise control over the coating thickness. By adjusting the blade's position or using different blade sizes, manufacturers can achieve the desired coating thickness, ensuring consistent performance across battery cells.

Secondly, the Wet Film Applicator ensures uniformity in the coating distribution. The flat blade sweeps across the substrate, spreading the slurry evenly and minimizing the risk of uneven coating thickness, which can lead to variations in battery performance.

Thirdly, this tool improves the efficiency and productivity of battery production. With the Wet Film Applicator, manufacturers can coat electrodes in a continuous and automated manner, ensuring a consistent and high-quality output. It reduces the dependency on manual application methods, which can be time-consuming and prone to human errors.

Lastly, the Wet Film Applicator contributes to the overall reliability and durability of batteries. The uniform coating achieved through this tool enhances the adhesion and stability of the active materials on the current collector, reducing the risk of detachment or delamination during battery operation. This, in turn, leads to improved battery performance and longer cycle life.

In conclusion, the Wet Film Applicator is an indispensable tool in the electrode coating process for battery production. Its ability to achieve precise and uniform coating thickness, enhance productivity, and improve battery performance makes it invaluable in ensuring the quality and consistency of batteries used in various applications, from portable electronics to electric vehicles.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat