For lithium-ion batteries, the usual positive collector fluid is aluminum foil and the negative collector fluid is copper foil. In order to ensure the stability of the collector fluid inside the battery, the purity of both requires more than 98%. With the continuous development of lithium technology, whether it is used for lithium batteries of digital products or batteries of electric vehicles, we all hope that the energy density of the battery is as high as possible, the weight of the battery is getting lighter and lighter, and the most important thing in the fluid collection is to reduce the thickness and weight of the fluid collection, intuitively reduce the volume and weight of the battery. There are three reasons why aluminum foil is used for the positive terminal of lithium-ion batteries, while copper foil is used for the negative terminal:

First, copper aluminum foil conductivity is good, soft texture, cheap price. As we all know, the principle of lithium battery is an electrochemical device that converts chemical energy into electric energy, so in this process, we need a medium to transfer the electric energy converted from chemical energy, here we need conductive materials. In common materials, metal materials are the best materials for electrical conductivity and in metal materials, the price is cheap and the electrical conductivity is good copper foil and aluminum foil. Meanwhile, in lithium batteries, we mainly have two processing methods: winding and laminating. Compared with winding, the electrode sheet used to prepare the battery needs to have certain softness, so as to ensure that the electrode sheet does not occur brittle break and other problems during winding. Among metal materials, copper aluminum foil is also a soft metal. Finally, consider the cost of battery preparation. Comparatively speaking, the price of copper aluminum foil is relatively cheap, and the world is rich in copper and aluminum resources.

Second, copper aluminum foil is relatively stable in the air. Aluminum is easy to react with oxygen in the air, forming a dense oxide film on the surface layer of aluminum, preventing further reaction, and this thin oxide film in the electrolyte also has a certain protective effect on aluminum. Copper itself is relatively stable in air and does not react in dry air.

Third, lithium battery positive and negative electrode potential determines the positive electrode with aluminum foil, negative electrode with copper foil, rather than the other way around. With high positive electrode potential, copper foil is easy to be oxidized at high potential, while aluminum has high oxidation potential, and the surface layer of aluminum foil has a dense oxide film, which also has a better protective effect on the internal aluminum. Both are used because they conduct electricity well, are soft (which may also help bond), are relatively common and inexpensive, and both can form a protective oxide film on the surface.

1. The lattice octahedral void size of aluminum is similar to that of Li, and it is easy to form metal interstitial compounds with Li. Li and Al not only form alloys with the chemical formula LiAl, but also may form Li3Al2 or Li4Al3. Due to the high activity of the reaction between metal Al and Li, metal Al consumes a large amount of Li, and its structure and form are also destroyed, so it cannot be used as a fluid collector for the negative electrode of lithium ion battery. However, in the process of battery charging and discharging, Cu only has a small capacity of lithium intercalation, and maintains the stability of its structure and electrochemical performance, so it can be used as a fluid collector for the negative electrode of lithium ion batteries. When Cu foil is at 3.75V, the polarization current increases significantly and linearly, and oxidation intensifies, indicating that Cu becomes unstable at this potential. However, the polarization current of aluminum foil is small and constant in the whole range of polarization potential, and no obvious corrosion phenomenon is observed, which maintains the stability of electrochemical performance. Al is suitable to be used as the positive collector fluid of Li-ion batteries because of its small lithium inlayment capacity and its ability to maintain electrochemical stability in the positive potential range of Li-ion batteries.

2. Copper/nickel surface oxide layer belongs to semiconductor, electron conduction, oxidation layer is too thick, impedance is large; And aluminum surface oxide layer alumina is an insulator, the oxide layer can not conduct electricity, but because it is very thin, through the tunnel effect to achieve electronic conductance, if the oxide layer is thick, aluminum foil conductivity level is poor, even insulation. General fluid collection in the use of the best before the surface cleaning, on the one hand to wash away the oil, at the same time can remove the thick oxide layer.

3.Positive electrode potential is high, aluminum thin oxide layer is very dense, can prevent fluid oxidation. The copper/nickel foil oxidation layer is more loose, in order to prevent its oxidation, the lower potential is better, and Li is difficult to form a lithium alloy with Cu/ nickel at low potential. However, if the copper/nickel surface oxidation is large, Li will react with copper/nickel oxide at slightly higher potential. Aluminum foil can not be used as a negative electrode, and LiAl alloying will occur at low potential.

4.Set fluid requires pure composition. The impurity of the composition of Al will lead to the surface film is not dense and point corrosion, and more importantly, the destruction of the surface film will lead to the formation of LiAl alloy.

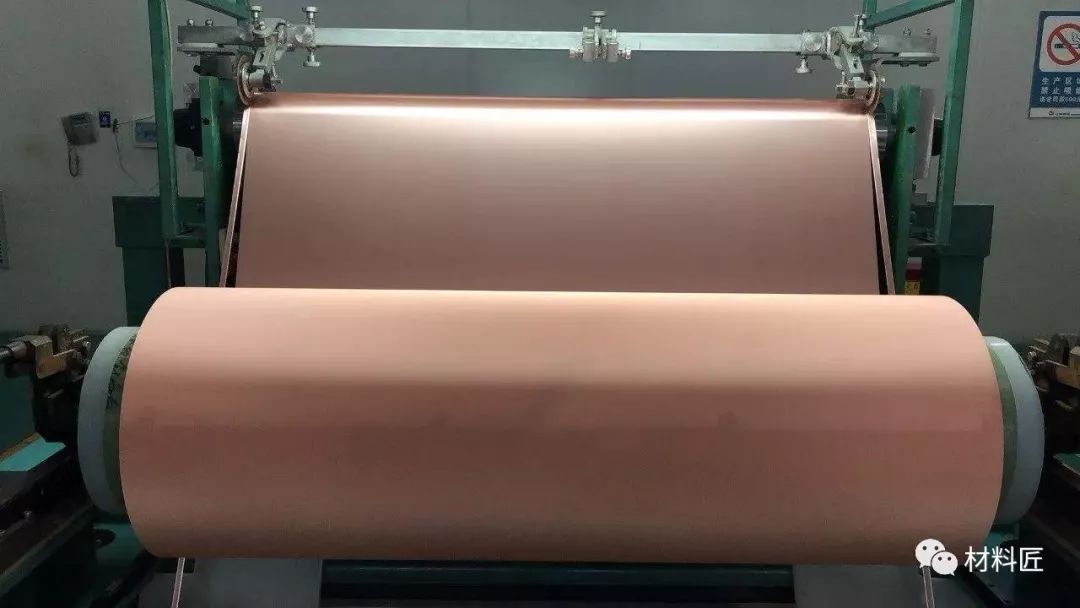

Copper aluminum foil thickness requirements for lithium electricity:

With the rapid development of lithium electricity in recent years, the development of lithium battery collector is also rapid. Positive aluminum foil has been reduced from 16um to 14um and then to 12um, and now many battery manufacturers have mass-produced 10um aluminum foil, even 8um. As for copper foil used for the negative electrode, due to its good flexibility, its thickness has been reduced from 12um to 10um and then to 8um. So far, 6um is used in mass production by a large number of battery manufacturers, and 5um/4um developed by some manufacturers is possible to be used. As lithium batteries have high purity requirements for copper aluminum foil used, the density of materials is basically at the same level. As the thickness of development decreases, the surface density also decreases correspondingly, and the weight of batteries naturally becomes smaller and smaller, which meets our demand for lithium batteries.

Surface roughness requirements of copper aluminum foil for lithium electricity:

In addition to the influence of the thickness and weight of the fluid collector on the lithium battery, the surface performance of the fluid collector also has a great influence on the production and performance of the battery. In particular, due to the defects of preparation technology, copper foils on the market are mainly single-sided wool, double-sided wool and double-sided coarse varieties. The asymmetric structure of the two sides leads to the asymmetric contact resistance of the coating on both sides of the negative electrode, so that the negative capacity of both sides can not be released evenly. At the same time, the asymmetry of the two sides also causes the bond strength of the negative coating is inconsistent, so that the charge and discharge cycle life of the negative coating on both sides is seriously unbalanced, thus accelerating the attenuation of the battery capacity.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat