Lithium-ion battery is a complex system, including positive electrode, negative electrode, separator, electrolyte, fluid collector and binder, conductive agent, etc., involving reactions including positive and negative electrode electrochemical reaction, lithium ion conduction and electron conduction, as well as heat diffusion. Lithium battery production process is relatively long, the production process involves more than 50 procedures.

Lithium batteries can be divided into cylindrical batteries, square batteries and soft pack batteries according to their forms. Their production processes are different to some extent, but the overall lithium manufacturing process can be divided into the first step (pole wafer manufacturing), the middle step (cell synthesis) and the last step (formation and packaging). Due to the high requirement of safety performance of lithium ion battery, the precision, stability and automation level of lithium battery equipment are highly required in the process of battery manufacturing.

Lithium equipment is a process equipment that uses positive and negative electrode materials, separator materials, electrolyte and other raw materials for manufacturing and production through orderly process. Lithium equipment has a significant impact on the performance and cost of lithium battery, and is one of the decisive factors. According to different technological processes, lithium electricity equipment can be divided into front section equipment, middle section equipment and rear section equipment. In the lithium electricity production line, the value ratio of front section, middle section and rear section equipment is about 4:3:3.

Lithium battery manufacturing process machine equipment

The production objective of the preceding process is to complete the manufacturing of (positive and negative) pole pieces. The main process of the first section of the process is: mixing, coating, roll press, splaying, production, die cutting, the equipment involved mainly includes: blender, coater, roll press, splaying machine, production machine, die cutting machine, etc.

Slurry mixing (equipment used: vacuum mixer) is to mix positive and negative solid-state battery materials evenly and then add solvent to stir into slurry. Slurry mixing is the beginning of the first step of the process, is to complete the subsequent coating, roll and other processes of the prior basis.

Coating (equipment used: coater) is the mixing slurry evenly coated on the metal foil and dried to make positive and negative electrode pieces. As the core link of the previous process, the execution quality of the coating process has a profound impact on the consistency, safety and life cycle of the finished battery, so the coater is the most valuable equipment in the previous process.

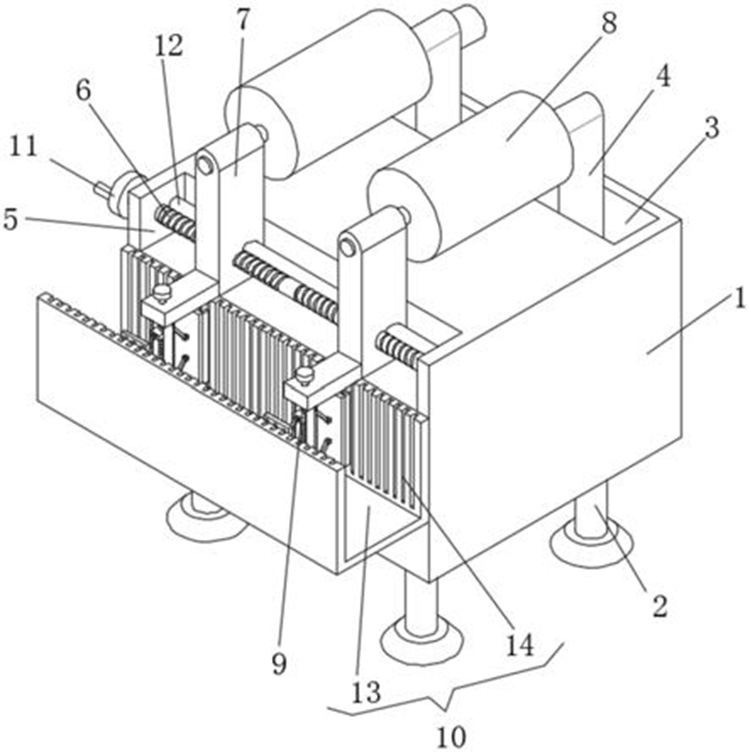

Roller pressing (equipment used: roller press) is the further compaction of coated electrode sheet, thereby increasing the energy density of the battery. After roller pressing, the flatness of the electrode sheet directly affects the finishing effect of the sequent cutting process, and the uniformity of the active substance of the electrode sheet indirectly affects the performance of the cell.

Slitting (equipment used: slitting machine) is to continuously slitting the wide whole roll of pole pieces into narrow pieces of a number of required widths. The fracture failure of the pole slice is caused by shear action during slitting. The flatness of the edge after slitting (no burr, no buckling) is the key to evaluate the performance of the slitting machine.

Making (equipment used: making machine) includes welding the pole lug after cutting the pole piece, sticking protective adhesive paper, pole lug coating or using laser cutting forming pole lug, etc., so as to be used for the subsequent winding process. Die cutting (equipment used: die cutting machine) is the coated pole sheet punching molding, for the follow-up process.

The production goal of the middle process is to complete the manufacturing of the battery cell. The technical route and production line equipment of the middle process of different types of lithium batteries are different. The essence of the middle process is the assembly process. Specifically, it is the (positive and negative) pole sheet made by the previous process to carry out orderly assembly with the separator and electrolyte. Due to the different energy storage structures of square (coil), cylindrical (coil) and soft pack (layer) batteries, there are obvious differences in technical routes and production lines of different types of lithium batteries in the middle process. Specifically, the middle process of the square and cylindrical battery main processes include: winding, liquid injection, packaging, the equipment involved mainly includes: winding machine, liquid injection machine, packaging equipment (shell machine, rolling slot machine, sealing machine, welding machine); The middle process of soft pack battery includes lamination, liquid injection and packaging. The equipment involved mainly includes lamination machine, liquid injection machine and packaging equipment, etc.

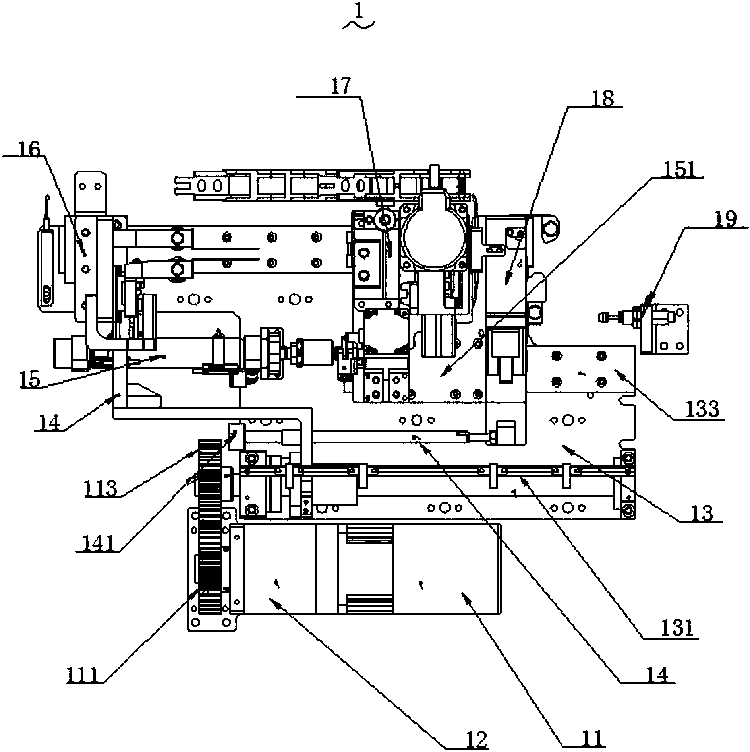

Winding (equipment used: winding machine) is to wind the pole film made by the production process or the winding die cutting mechanism into the battery cell of lithium ion battery, mainly used for square, round lithium battery production. The winding machine can be subdivided into square winding machine and cylindrical winding machine, which are respectively used for the production of square and cylindrical lithium batteries. Compared with cylindrical winding, the square winding process requires higher tension control, so the technical difficulty of the square winding machine is greater.

Lamination (equipment used: Lamination machine) is the single pole lamination made in die cutting process into lithium ion battery cell, mainly used in the production of soft pack battery. Compared with square and cylindrical cell, soft pack cell has obvious advantages in energy density, safety and discharge performance. However, the single stacking task of the laminating machine involves the parallel of multiple sub-processes and the collaboration of complex mechanisms, so complex dynamic control problems are needed to improve the laminating efficiency. The speed of the winding machine is directly related to the winding efficiency, and the efficiency enhancement method is relatively simple. At present, the production efficiency and yield of laminated cell are different from that of wound cell.

Liquid injection machine (equipment used: liquid injection machine) is to inject the electrolyte of the battery into the cell.

Cell packaging (equipment used: shell machine, slotting machine, sealing machine, welding machine) is to put the core into the cell shell.

The production goal of the latter process is to complete the packaging. Up to the middle process, the functional structure of lithium battery cell has been formed. The significance of the latter process is to activate it, and after testing, sorting and assembly, the finished product of lithium battery with safe use and stable performance is formed. The main process of the latter part of the process includes: formation, volume separation, detection, separation, etc. The equipment involved mainly includes: charging and discharging machine, detection equipment, etc.

Formation (device used: charge-discharge machine) is to activate the cell through the first charge, during which an effective passivation film (SEI film) is generated on the negative surface to achieve the "initialization" of the lithium battery. Capacitance separation (equipment used: charge and discharge machine), namely "analytical capacity", is to charge and discharge the formed cell in accordance with the design standard, in order to measure the capacitance of the cell. Charge-discharge machine is the most commonly used post-core equipment for charging and discharging the cell through the formation and volume separation process. The minimum unit of charge and discharge machine is the "channel", a "unit" (BOX) by a number of "channels" combination, multiple "units" together, constitute a charge and discharge machine.

Detection (equipment used: detection equipment) should be carried out before and after charging, discharging and standing; Sorting is to classify and select batteries after formation and volume separation according to certain standards according to the test results. The significance of the detection and sorting process is not only to exclude unqualified products, because in the practical application of lithium ion batteries, the cell is often combined in parallel and series, so the selection of similar performance of the cell, help to make the overall performance of the battery to achieve the best.

The production of lithium battery cannot be separated from the production equipment of lithium battery. In addition to the materials used in the battery itself, the manufacturing process and production equipment are important factors to determine the battery performance. In the early stage, Chinese lithium equipment mainly depended on imports. After several years of rapid development, Chinese lithium equipment enterprises have gradually caught up with Japanese and South Korea equipment enterprises in technology, efficiency, stability and other aspects, and have advantages in cost-effective, after-sales maintenance and other aspects. At present, domestic lithium equipment enterprise cluster has been formed, and become China's high-end equipment business card into the international market. With the vertical alliance of lithium electric leading and production expansion at sea, lithium electric equipment benefit from downstream production expansion ushered in a new period of rapid growth of opportunities.

PS: Aooser has all the equipment mentioned above. If you are interested, please feel free to contact us.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat