There are many variations on the names of power batteries

In addition to battery enterprises such as Ningde Times, vehicle enterprises such as Tesla, BYD, Guangzhou Automobile, SAIC Motor, Great Wall, etc., have their own power battery research and development technology. In the new battery materials have not yet broken through, these with different names of battery technology, in fact, mainly in the battery structure of innovation, which is also one of the important grasp of new energy vehicle enterprises. Through the optimization and innovation of battery structure, automobile companies hope to improve the endurance, fast charging speed and performance of electric vehicles, as well as the safety of batteries. So, what are these different battery technologies, and what are their respective advantages?

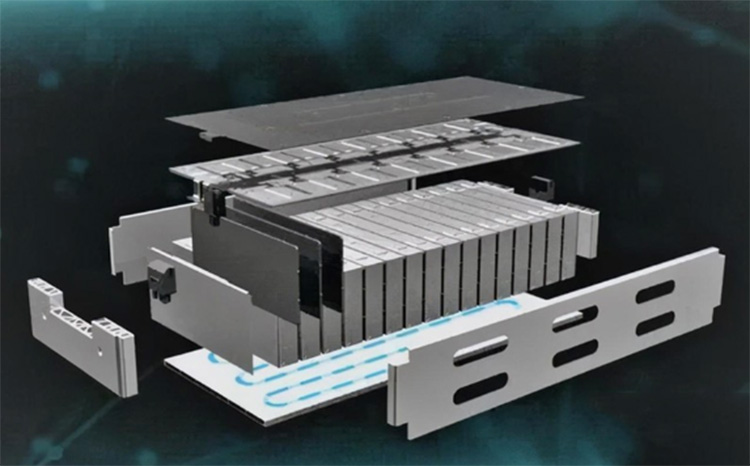

At present, Ningde Times, the "leader" of power battery in China and even the world, pioneered mode-free battery pack in 2019, which is the first generation of CTP technology. The traditional battery adopts the assembly mode of cell - module - battery pack. The so-called CTP is to directly integrate a large number of cells in series and parallel into the battery pack, omitting the module.

By eliminating the modules that are wrapped around the cell, the battery pack has more space to arrange the cells, increasing the volume utilization of the battery pack and increasing the energy density of the system, thus increasing the range of the vehicle. At the time, the technology enabled battery pack volume utilization to exceed 50 percent. Since then, CTP has become the focus of domestic battery enterprise layout.

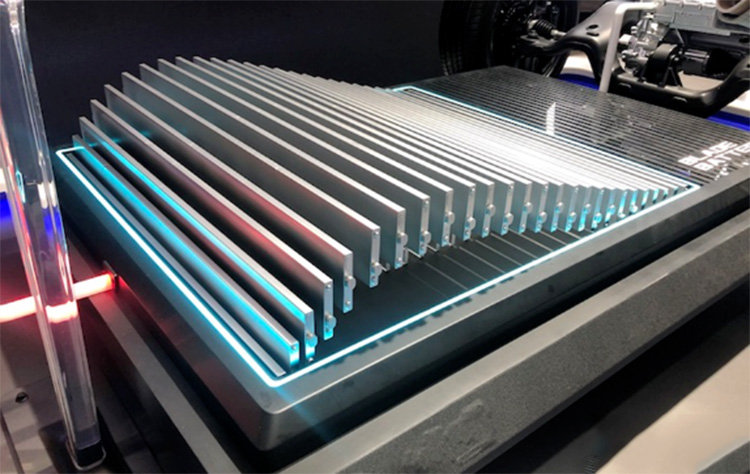

Now the third generation of CTP technology in Ningde era has been developed, which is the Kirin battery released last year. The volume utilization rate has reached 72%. The most direct effect is to increase the energy density of terpolymer lithium battery to 255Wh/kg, and the energy density of lithium iron phosphate battery system to 160Wh/kg. Its endurance, fast charge, safety, life, efficiency, and low temperature performance has been comprehensively improved, and claimed that in some performance "beat Musk, more than 4680", triggered strong attention in the industry, but also boosted Ningde times stock price surge.

For comparison, the Kirin battery pack, with the same chemical system and the same battery size, can deliver 13% more power than the Tesla 4680 battery. It is understood that in terms of endurance, equipped with three-way lithium Kirin battery can achieve a vehicle endurance of 1000 kilometers. In terms of fast charging, Kirin battery is the first battery cell cooling technology, support 5 minutes fast hot start, and 10 minutes fast charge up to 80%.

Tesla's 4680 cylinder battery has two main selling points, one is strong endurance, the other is lower cost. Compared to the previous Tesla 2170 battery, the 4680 battery has five times the energy and six times the power of the past, with an energy density of up to 300Wh/kg. At the same time, the 4680 battery costs 14% less than the original battery. This is also Tesla dare to set off the electric car price war one of the confidence.

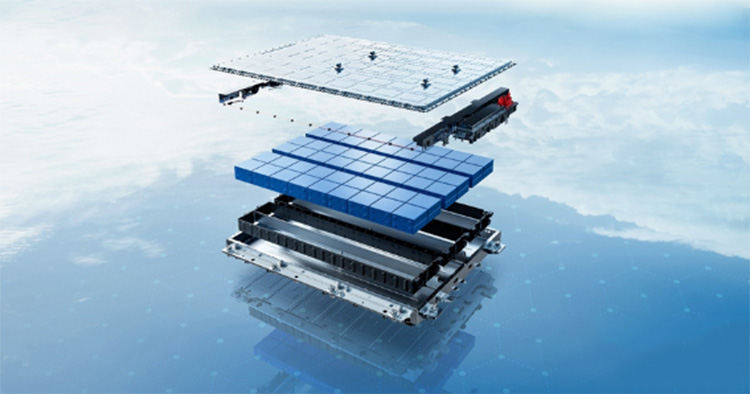

Byd's "blade battery," so named because it looks like a blade, refers to the fact that the battery is flat and long like a blade, and closely resembles the shape of a chewing gum, and focuses on safety. In the words of BYD Chairman Wang Chuanfu, "Blade battery is BYD's determination to completely end the safety pain point of new energy vehicles, to bring the global power battery technology route back to the right track, so that the label of" spontaneous combustion "in the dictionary of new energy vehicles."

After the official release of blade battery in March 2020, BYD gradually applied blade battery in all models, realizing the large-scale application of blade battery.

The results of the acupuncture test show that the surface temperature of the three-way lithium battery exceeds 500 degrees at the moment of acupuncture, the surface temperature of the traditional block lithium iron phosphate() battery reaches 200-400 degrees after puncture, and the surface temperature of BYD's blade battery is only 30-60 degrees. Ouyang Minggao, an academician at the Chinese Academy of Sciences, said the design of the blade battery, which produces less heat and dissipates heat quickly when short-circuited, is "very good".

In terms of battery life, blade batteries increase the energy density of traditional lithium iron phosphate batteries by 50 percent. And because they do not use nickel or cobalt, blade batteries are much cheaper than conventional lithium-ion batteries.

In terms of safety and service life, BYD blade batteries do have outstanding advantages, but the fast charge may be its current performance weakness, 80 percent charge takes 30 to 40 minutes to complete, and full takes about an hour.

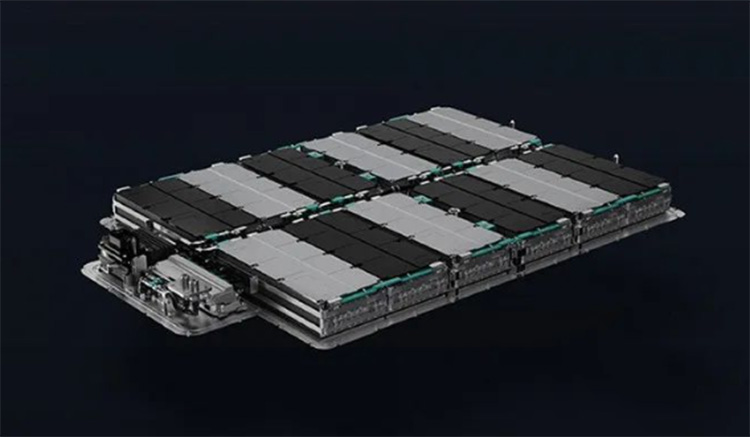

The magazine battery launched by GAC Aean in 2021 also focuses on safety. This battery structure is composed of multiple cells into a battery module, and then multiple modules into a whole power battery pack, which looks like a magazine.

The technology uses heat-resistant materials and insulation between cells so that if a thermal runaway occurs in one cell, it does not spread to the others. The battery uses the latest battery management system, which can adjust the temperature of the battery system to ensure the safety performance of the battery and the battery life. At that time, the manufacturer carried out acupuncture heat diffusion test on the whole pack of ternary lithium batteries equipped with the safety technology of the magazine battery system. Not long ago, Ian also carried out a gun test on magazine battery 2.0, and realized the world's first battery gun pack without fire.

However, compared with the laminated design of blade battery, magazine battery still adopts the modular design, and the energy density of its battery pack is lower than that of blade battery. With the same volume of power battery pack, blade battery can provide more power and longer endurance. Also, because of the modular design, magazine batteries are more expensive to manufacture than blade batteries.

As a new-generation battery jointly developed by SAIC and Ningde Times, Rubik's Cube battery was first installed on SAIC MG pure electric vehicle MULAN, and later on iMAX 8 EV and other models. Saic Rubik's Cube battery focuses on the standardization of "ONE PACK", and has the characteristics of "ultra-thin and flat".

The Rubik's Cube battery is a standard battery pack that comes in three sizes with the same length, width and slightly different height, making it easier and faster to "change". The battery pack adopts LBS lying cell and advanced CTP technology. The thickness of the whole battery pack is as low as 110mm, which makes the space utilization rate of the vehicle greater. At the same time, the battery energy density can reach 180Wh/kg, and the efficiency is greatly improved.

There are many kinds of power batteries. At present, it is not possible to say whose batteries must have absolute advantages or be at complete disadvantages. Objectively speaking, none of them can fully meet the driving needs of consumers today. So manufacturers are also trying to develop batteries that are more energy-dense but less costly.

At present, in addition to the innovation in the battery structure, all the major enterprises will focus on the solid-state battery industry, solid-state battery has become the core technology for the major automobile manufacturers to compete for the right to speak of the future pure electric vehicle. Nissan, BMW, Ningde Times, Nextev, SAIC Motor, Guangzhou Automobile, etc., all indicated that they have made progress in the research and development of solid-state batteries.

Fu Neng technology chairman Wang Yu recently said in an interview with the media, the power battery in the technical level there are still more problems: on the one hand, the energy density is not high enough, the range is not long enough, some vehicles have the trend of false; Battery packs, on the other hand, are limited in size, making it difficult to significantly improve battery life. In addition, due to the impact of cost compression, power batteries are gradually tilted towards lithium iron phosphate. The evolution of lithium-ion batteries, he argues, starts with liquid, but ends with solid.

Solid-state batteries are popular in the first place because they use a solid electrolyte instead of the electrolyte and diaphragm of traditional lithium-ion batteries. Solid-state batteries are safer, have higher energy density, and have better cycle performance than traditional lithium-ion batteries. Second, solid-state battery technology is expected to dramatically reduce the cost of electric vehicles, with some research institutions estimating that the cost of mass-produced solid-state batteries is only 40% of that of current lithium-ion batteries.

However, while some companies claim that solid - and semi-solid - state batteries are on the way, there are technical reasons why large-scale commercialization of solid-state batteries is unlikely in the near future.

As the most important component of the new energy vehicle, the performance of the power battery is one of the factors that consumers are most concerned about, and it is also one of the most important competitive chips of the new energy vehicle brand in the market. Therefore, the major brands of power battery constantly seek breakthrough and improvement in battery technology, a variety of technical routes competition, this war will continue.

For consumers, this battle can stimulate each other, accelerate the development of innovation, promote the continuous progress of power battery safety and comprehensive performance, and at the same time, different batteries also give consumers more choices according to their needs.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat