Lithium ion button battery is mainly composed of the following parts: positive case, negative case, (positive/negative) electrode, separator, spacer, conical spring, electrolyte.

The C in the common regular commercial button battery CR2032 means that the positive terminal is MnO2, and the BR series, B means that the positive terminal is fluorocarbon. C or B represents the power supply system, and R represents the round shape of the battery. The first two digits are the diameter (unit: mm), and the last two digits are the thickness (unit: 0.1mm). For example, CR2032 has a diameter of 20 mm and a thickness of 3.2 mm.

The following figure shows the CR2032 button battery case. The positive case is larger, while the negative cas has a small mesh structure on the surface, so the general assembly process starts from the negative case.

Figure 1 CR2032 button battery positive shell (left), negative shell (right)

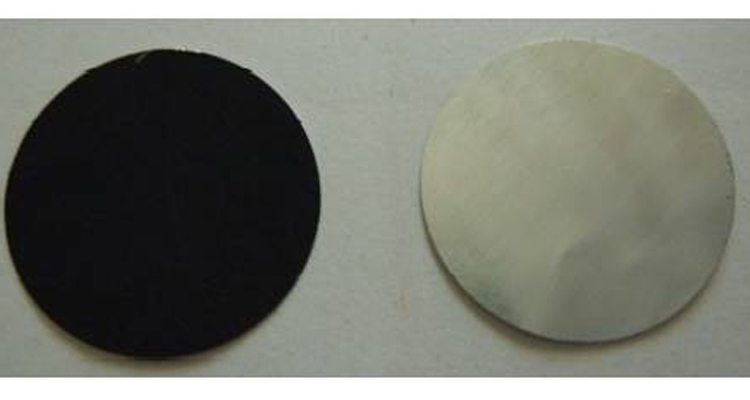

The preparation process of electrode sheet has an important impact on the full play of electrochemical properties, which will be explained in 2.1 and briefly introduced here. The following figure shows the electrode plate prepared by the positive electrode material.

Figure 2 Positive electrode (left) and aluminum foil (right)

The positive and negative collector fluids of lithium ion battery electrode are aluminum foil and copper foil respectively. If one-way smooth foil is used, coat it on rough surfaces to increase the binding force between the collector and the material. The thickness of the foil is not strict, but the uniformity of the surface density of the foil is relatively high. Silicon based anode materials are generally coated with carbon copper foil to improve adhesion, reduce contact resistance, in order to increase the reproducibility of test results, improve the charge-discharge cycle performance What kind of electrode is a good electrode? These aspects should be met: (1) the slurry coating is uniform, no obvious uneven thickness can be observed, especially thin places can even be observed bright aluminum foil; (2) the pole piece remains intact and round without damage, and there is no burr around it as far as possible; (3) There is no particulate matter in the coating area and no obvious powder dropping phenomenon.

Laboratory separators are usually Celgard2400 or other products of the Celgard series, stamped into small round sheets for use, slightly larger than the diameter of the positive and negative electrodes. Separator can be selected according to different battery performance requirements. For the selection and parameters of diaphragm, please see the introduction of the selection and parameter significance of lithium battery separator in the later period. What does the separator do? Simply put, if there is no separator, the positive and negative electrodes will directly contact, that is, short circuit will occur, which is why some batteries to inhibit the generation of lithium dendrites, is to prevent its puncture separator, cause local short circuit, and cause safety accidents. Separator is generally made of polyethylene and other polymer materials, non-conductive, its structure has many microholes, allow lithium ions through, although it is an insulator, but "do not allow electrons through the statement is not accurate."

The diameter of the negative electrode is slightly less than the diameter of the negative case. The diameter of the lithium electrode of CR2032 is 15.8mm. The laboratory often uses the punching die with a diameter of 14mm (corresponding to the CR2032 button battery) to flush the positive electrode. It is worth noting that lithium sheets are soft and easy to deform, so the positive case (because it is larger) can be used to flat10 the deformed Lithium chips before loading the battery. Moreover, lithium metal is easy to oxidize and deteriorate in air, and it is easy to explode in contact with water, so the purchased lithium metal chip needs to be opened in the glove box, and pay attention to not damaging the glove when opened.

Figure 3 Lithium metal chip suitable for CR2032 battery

The spacer is a round aluminum sheet with the same diameter as the lithium sheet. In the experiment, different specifications and thicknesses can be purchased according to the demand.

Note: Spacer, positive and negative shells and other components should be cleaned repeatedly with alcohol before use, and then dried in an air drying oven.

Figure 4 Spacer

Conical spring mainly plays the role of supporting the battery. If there is no conical spring, the battery will be pressed flat in the step of pressing the battery, and the internal components may be crushed. Conical spring is only added in the negative side, but if the positive and negative terminals are added with conical spring, the voltage battery step can not be closed, resulting in electrolyte and air contact, and the experiment failed.

Figure 5 Conical Spring

Different materials generally correspond to different electrolyte, in the experiment do not figure easy to settle, small batch of electrolyte can find the company to ask, generally will give. Individual special electrolyte, such as low temperature electrolyte, may need to buy, the price is not low. 1.8 Selection of materials The active materials of positive and negative electrodes are generally powder materials. The particle size should not be too large to facilitate uniform coating. At the same time, the test results should be avoided due to the limitation of material dynamics properties and the non-uniformity of the pole plate caused by large particles. The maximum particle diameter (Dmax) of anode and cathode materials used in laboratory research is generally less than 50μm, and the Dmax of lithium electric materials used in industry is generally less than 30μm. Large particles, aggregates or nanoscale materials are often sifted or ground. The common conductive agents for lithium batteries are carbon-based conductive agents, including acetylene black (AB), conductive carbon black, Super P, 350G and other conductive materials. Common binder systems include polyvinylidene fluoride - oil based system [poly(vinylidene fluoride), PVDF system] and polytetrafluoroethylene - water based system [poly(fluortetraethylene), commonly referred to as emulsion, PTFE system]. SBR (styrene butadiene rubber) emulsion, etc. NMP (N- methyl pyrrolidone) is often used as solvent in oil system.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat