Introduction: Lithium-ion battery assembly contains multiple steps, each process contains knowledge and knowledge, which has a great impact on the final performance of the battery. Among them, rolling treatment of positive and negative electrode pieces is an essential process. The main purpose of rolling is to control the electrode pieces in the designed range, enhance the peeling strength of the electrode pieces, and reduce the transmission distance of lithium ions. Due to the different material system, the roll pressure rebound of positive electrode sheet is relatively small, while the roll pressure rebound of negative electrode sheet is larger. Therefore, almost all domestic power battery enterprises for the positive electrode piece only a roll press(our company provides the roller pressing machines for electrode), there is no disagreement; As for the negative electrode piece, some enterprises roll once, some enterprises choose to roll twice, the difference is large.

Recently, researchers from Samsung SDI and Hanyang University in Korea have conducted a comparative study on the single roll compression and double roll compression of the graphite negative electrode sheet. The results show that the double roll compression of the negative electrode sheet can not only prevent the cracking and pulverization of the negative particles, but also make the voidage distribution in the anode sheet more uniform, which ultimately leads to the increase of the electrolyte wettability and the decrease of the electrode resistance value. The specific results are as follows:

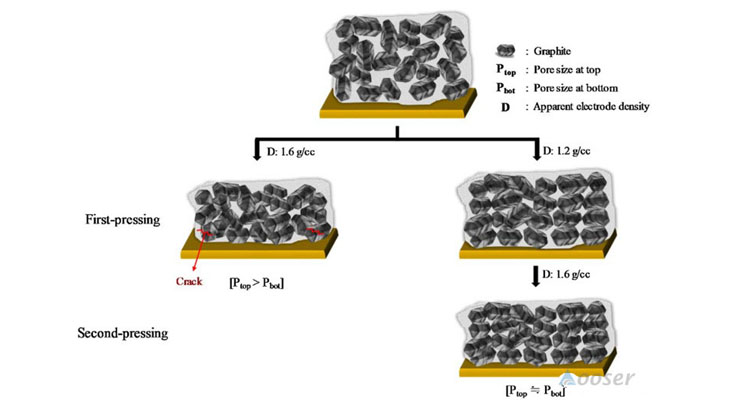

FIG. 1. Schematic diagram of primary and secondary roller pressing principle of negative electrode sheet.

The principle of single roll and double roll of negative electrode plate is shown in Figure 1. The so-called one roll is only one roll to reach the designed thickness and density of the pole plate; The second roll is to first roll the pole piece to a certain thickness, and then through the second roll to achieve the design thickness and density. The difference between the two is that the active particles are easily broken and pulverized by one roll pressing, and the aperture above the pole plate (far away from the copper foil) is larger than that below the pole plate (near the copper foil). Secondary roller pressing can not only reduce the rupture of active particles as much as possible, but also make the aperture distribution in the electrode plate uniform, so as to promote the electrolyte infiltration, and finally improve the performance of the battery.

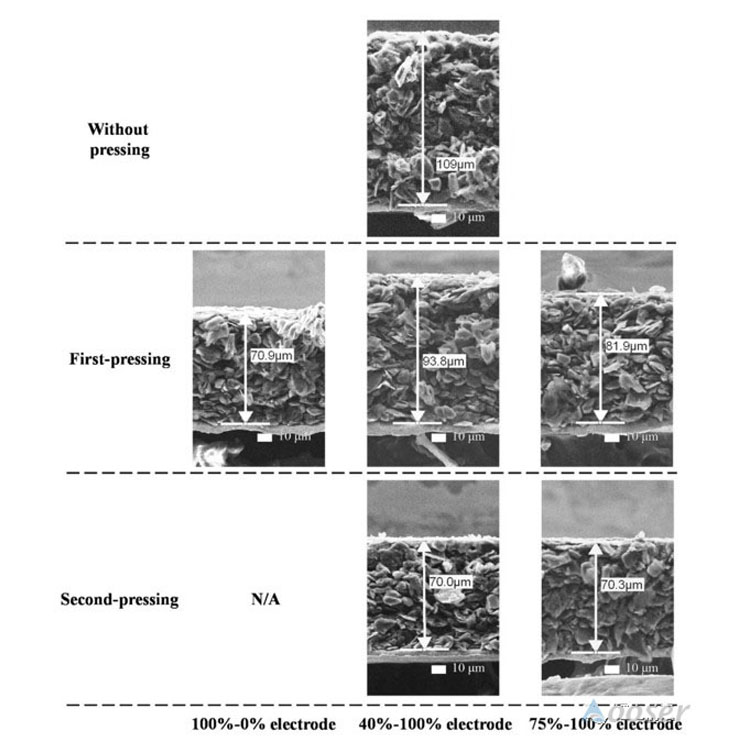

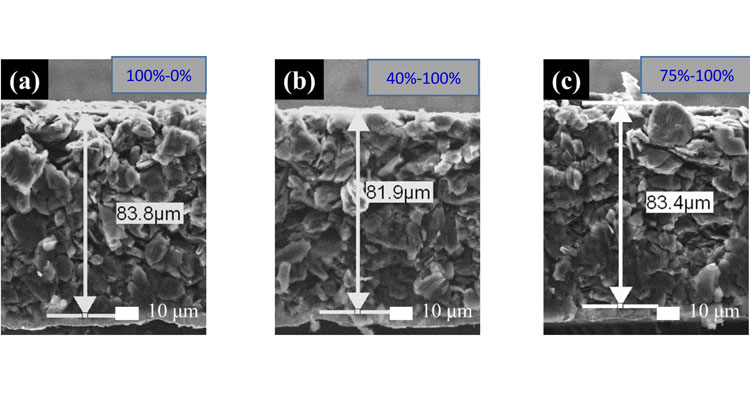

Figure 2. SEM image and size information of negative electrode sheet after three different roller pressing methods.

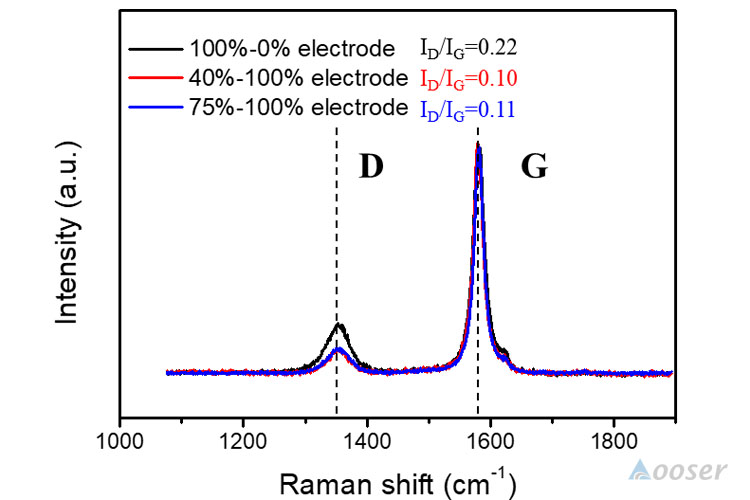

Figure 3. Raman characterization results of negative electrode sheet after three different roller pressing methods.

Firstly, the microstructure and size of the negative electrode sheet after three different roller compression methods were compared. In FIG. 1, 100%-0% refers to that the electrode is only rolled once, while 40%-100% and 75%-100% respectively roll the electrode sheet for the first time, the depth of the roll is 40% and 75% of the original thickness, and then roll for the second time to reach the design value. As shown in FIG. 1, the initial thickness of the active layer of the electrode sheet is 109μm, which can reach about 70μm as required by the design no matter it is rolled once or twice, and no difference can be seen in the structure of the two rolling methods only from the microscopic morphology. Subsequently, the author conducted Raman characterization of graphite active particles in rolled electrode flakes, and the results are shown in Figure 3. In Raman signals, ID/IG represents the defect level of graphite particles, and higher ID/IG means more defects of graphite particles. It can be seen from Figure 3 that the ID/IG value of the anode graphite in the single-roll compression is 0.22, while the ID/IG value of the anode graphite in the two-roll compression is only half of that in the single-roll compression, indicating that the damage degree of the graphite particles in the two-roll compression is relatively small.

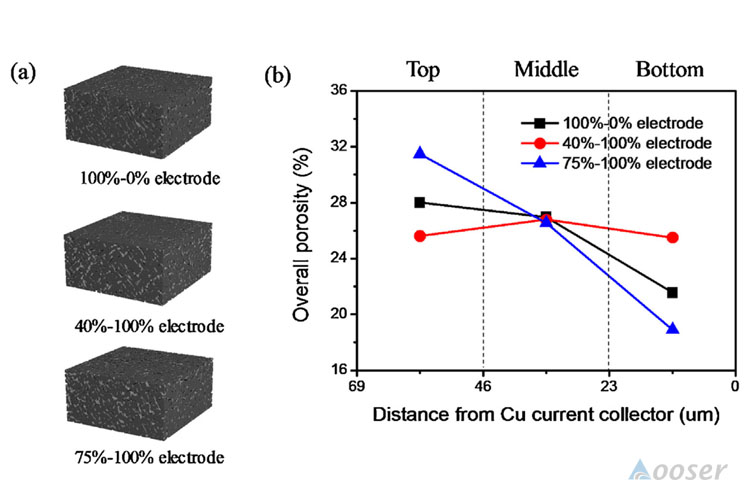

Figure 4. The (a)3D-XRM reconstructed image and (b) the porosity comparison of the upper, middle and lower parts of the negative electrode sheet after roller pressing in three different ways.

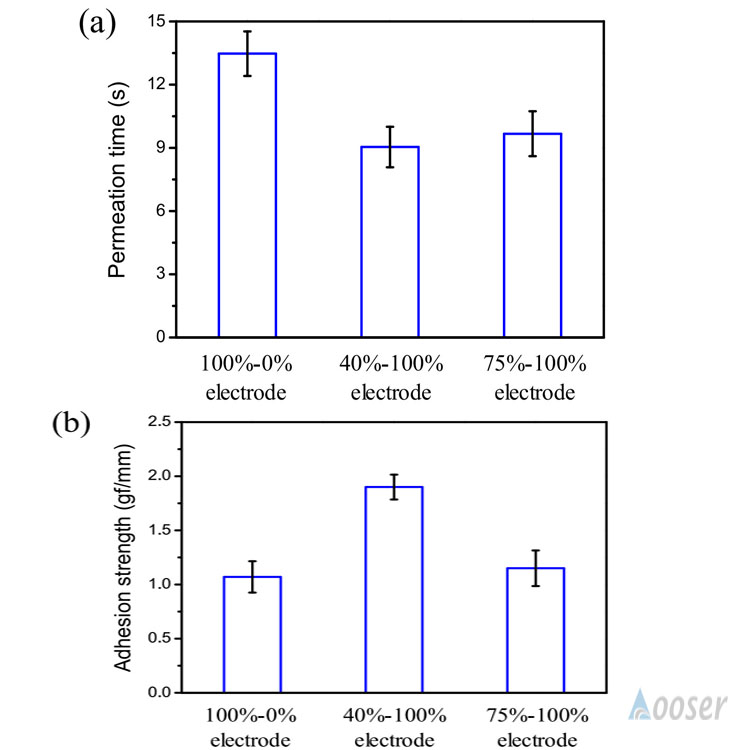

Figure 5. (a) comparison of electrolyte infiltration and (b) comparison of adhesion of negative electrode sheet after roller pressing by three different methods.

The pore size distribution and the bonding force of the wafer are also important indexes to evaluate the roll pressing process. As shown in FIG. 4, the 3D-XRM reconstruction image of the electrode piece after roll pressing shows that the aperture of the electrode piece after two rolls pressing is significantly larger than that after one roll pressing, and the distribution of the aperture of the electrode piece after 40%-100% roll pressing is more uniform. And no matter the electrolyte wettability or the adhesive force of the electrode sheet, the electrode sheet with 40%-100% roller press twice has better performance.

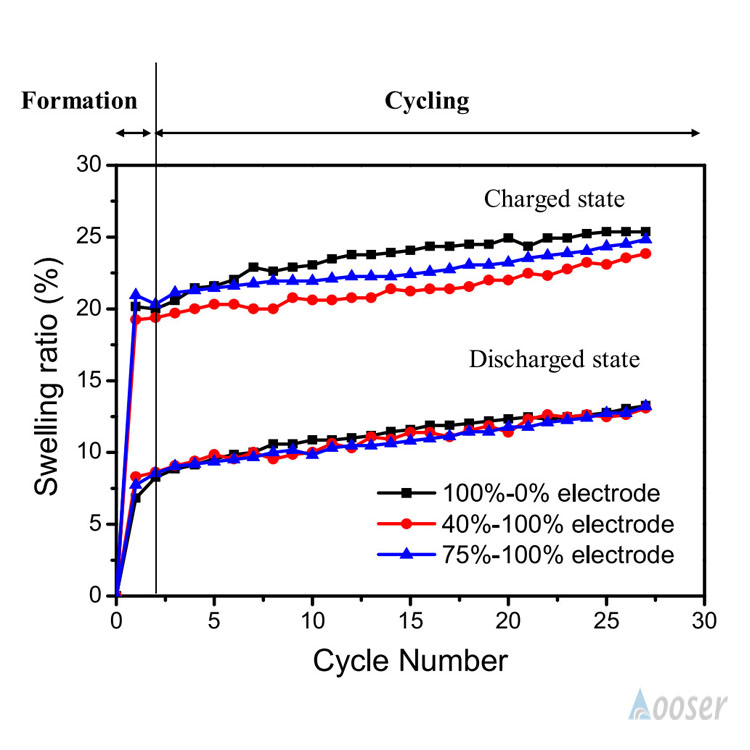

FIG. 6. Expansion comparison of LiCoO2 soft pack cells made of negative electrode rolled in three different ways during formation and circulation.

FIG. 7. SEM image and size information of negative electrode after 25 weeks with three different roller pressure modes.

The expansion of battery mainly comes from the negative electrode. The author made LiCoO2 soft pack battery by rolling graphite anode in three different ways, and compared the expansion. As shown in Figure 6, the expansion rates of the soft-pack battery made of the negative electrode sheet rolled by 40%-100% twice are 19.23% and 4.47% respectively in the formation and cycle stages, which is the lowest among the three groups of batteries. The authors believe that the uniform pore size distribution enables the 40%-100% double roller pressed negative electrode sheet to be well infiltrated by the electrolyte and release the pressure of forming and circulating electrode sheet, so as to obtain the minimum expansion rate results. As shown in FIG. 7, the initial design thickness of the active layer of the negative electrode sheet is 70μm. After 25 weeks of cycling, the active layer thickness of the negative electrode sheet is 83.8μm, 81.9μm and 83.4μm for 100%-0% primary roll, 40%-100% double roll and 75%-100% double roll, respectively. The thickness of 40%-100% double roller pressed electrode sheet is the lowest, which is consistent with the result of expansion rate of soft pack battery. In addition, the authors also analyzed the cycle performance, multiplier performance and electrochemical impedance spectra of the soft pack cells made of three kinds of pole plates. The results all show that the soft pack cells made of 40%-100% double roll compression of pole plates have the best performance, which will not be repeated here.

Summary: Some domestic enterprises have begun to apply the double roll pressing process of negative electrode sheet. Battery technology is tiring and boring, leading to a lot of people do not want to do it, but it does contain a wealth of scientific truth, even each process to write a book alone.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat