With the use of lithium battery, battery performance continues to decline, mainly for capacity attenuation, internal resistance increase, power decline, the change of battery internal resistance is affected by temperature, discharge depth and other conditions. Therefore, the factors affecting the internal resistance of the battery were discussed in combination with the structural design of the battery, the performance of the raw materials, the manufacturing process and the operating conditions.

In the design of battery structure, in addition to the riveting and welding of the battery structure itself, the number, size and position of the battery pole lug directly affect the size of the battery internal resistance. To a certain extent, increasing the number of pole ears can effectively reduce the internal resistance of the battery. The position of the pole lug also affects the internal resistance of the battery. The internal resistance of the wound battery with the pole lug position at the head of the positive and negative electrodes is the largest, and compared with the wound battery, the laminated battery is equivalent to dozens of small batteries in parallel, and its internal resistance is smaller.

1. Active materials for positive and negative electrodes

The positive electrode material in lithium battery is the lithium storage side, which more determines the performance of lithium battery. The positive electrode material mainly improves the electron conduction ability between particles through coating and doping. For example, doping Ni enhances the strength of P-O bond, stabilizes the structure of LiFePO4/C, optimizes the cell volume, and effectively reduces the charge transfer impedance of the positive electrode material. The increase of activated polarization, especially the negative polarization, is the main reason for the serious polarization. When the particle size of the negative electrode is reduced by half, the activation polarization can be reduced by 45%. Therefore, as far as battery design is concerned, the improvement of anode and cathode material itself is also indispensable.

2. Conductive agent

Graphite and carbon black are widely used in the field of lithium battery because of their good properties. Compared with graphite conductive agents, the positive electrode with carbon black conductive agents has better magnification performance. Because graphite conductive agents have flake particle morphology, pore torsification coefficient increases greatly at high magnification, and discharge capacity is easily restricted during Li liquid phase diffusion process. The internal resistance of the battery with CNTs is smaller, because compared with the point contact between graphite/carbon black and the active material, the fibrous carbon nanotubes and the active material are line contact, which can reduce the interface impedance of the battery.

3. Collect fluids

It is an important means to improve the performance of lithium battery to reduce the interface resistance between fluid collector and active substance and to increase the bond strength between them. The conductive carbon coating and corona treatment on aluminum foil can effectively reduce the interface impedance of battery. Compared with the normal aluminum foil, the use of carbon coated aluminum foil can reduce the internal resistance of the battery by about 65%, and can reduce the increase of the internal resistance of the battery during use. The AC internal resistance of aluminum foil treated by corona can be reduced by about 20%. In the 20%-90% SOC range commonly used, the DC internal resistance is generally small, and its increase gradually decreases with the increase of discharge depth.

4. Separator

The ion conduction inside the battery depends on the diffusion of Li ions in the electrolyte through the porous membrane. The wetting ability of the membrane is the key to form a good ion flow channel. When the membrane has a higher liquid absorption rate and porous structure, the conductivity can be improved, the battery impedance can be reduced, and the ratio performance of the battery can be improved. Compared with the ordinary base film, the ceramic separator and the coated separator can not only greatly improve the high-temperature shrinkage resistance of the diaphragm, but also enhance the moisture absorption capacity of the separator. Adding SiO2 ceramic coating on the PP separator can increase the liquid absorption of the separator by 17%. When the PP/PE composite membrane was coated with 1μm PVDF-HFP, the membrane liquid absorption rate increased from 70% to 82%, and the internal resistance decreased by more than 20%.

From the aspects of process technology and service conditions, the factors that affect the internal resistance of batteries mainly include:

1. Paste

The uniformity of slurry dispersion affects whether the conductive agent can be evenly dispersed in the active substance and in close contact with it, which is related to the internal resistance of the battery. By increasing the high speed dispersion, the uniformity of slurry dispersion can be improved, and the internal resistance of the battery is smaller. By adding surfactants, the distribution uniformity of the conductive agent in the electrode can be improved, and the electrochemical polarization can be reduced and the median discharge voltage can be increased.

2. Coat

Surface density is one of the key parameters of battery design. When the battery capacity is given, increasing the extreme one-sided density will inevitably reduce the total length of the fluid collector and diaphragm, and the internal resistance of the battery will decrease accordingly. Therefore, within a certain range, the internal resistance of the battery will decrease with the increase of surface density. The migration and detachment of solvent molecules during coating drying is closely related to the temperature of the oven, which directly affects the distribution of binder and conductive agent in the electrode sheet, and then affects the formation of conductive grid inside the electrode sheet. Therefore, the temperature of coating drying is also an important process to optimize the battery performance.

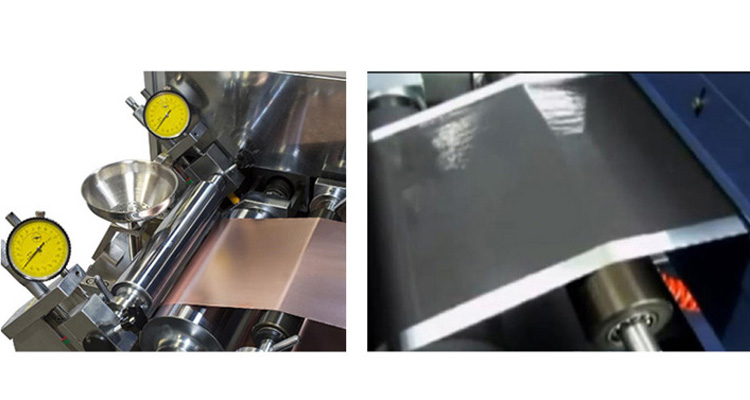

3. Roll press

To a certain extent, the internal resistance of the battery decreases with the increase of the compaction density, because the increase of the compaction density, the distance between the raw material particles decreases, the more contact between particles, the more conductive Bridges and channels, and the battery impedance decreases. The compaction density is controlled mainly by the thickness of roll press. Different roll thicknesses have a great influence on the internal resistance of the battery. When the roll thicknesses are large, the contact resistance between the active substance and the fluid collector increases because the active substance is not tightly rolled, and the internal resistance of the battery increases. Moreover, after the battery cycle, a crack occurs on the positive electrode surface of the battery with a larger thickness, which further increases the contact resistance between the active substance on the electrode surface and the fluid collector.

4. Pole plate turnover time

The internal resistance of the battery increases slowly due to the influence of the carbon coating on the surface of lithium iron phosphate and the interaction between lithium iron phosphate and lithium iron phosphate. When it is used for a long time (more than 23h), the internal resistance of the battery increases significantly due to the reaction of lithium iron phosphate with water and the bonding effect of the adhesive. Therefore, the turnover time of pole plate should be strictly controlled in actual production.

5. Liquid injection

The ionic conductivity of the electrolyte determines the internal resistance and rate characteristics of the battery. The conductivity of the electrolyte is inversely proportional to the viscosity of the solvent, and is also affected by the concentration of lithium salt and the anion size. In addition to the research on the optimization of conductivity, the amount of liquid injection and the infiltration time after injection also directly affect the internal resistance of the battery. A small amount of liquid injection or insufficient infiltration time will cause the internal resistance of the battery to be larger, thus affecting the capacity of the battery.

1. Temperature

The effect of temperature on the size of the internal resistance is obvious. The lower the temperature, the slower the ion transport inside the battery, and the greater the internal resistance of the battery. Battery impedance can be divided into volume phase impedance, SEI film impedance and charge transfer impedance. The volume phase impedance and SEI film impedance are mainly affected by the ionic conductivity of the electrolyte, and the changing trend at low temperature is consistent with that of the electrolyte conductivity. Compared with the increase of bulk phase impedance and SEI film resistance at low temperature, the charge reaction impedance increases more significantly with the decrease of temperature. Below -20℃, the ratio of charge reaction impedance to the total internal resistance of the battery reaches almost 100%.

2.SOC

When the battery is under different SOC, its internal resistance is also different. In particular, the DC internal resistance directly affects the power performance of the battery, and thus reflects the battery performance in the actual state: The DC internal resistance of lithium battery increases with the increase of DOD, and the internal resistance is basically unchanged in the discharge range of 10% to 80%. Generally, the internal resistance increases significantly in the deeper discharge depth.

3. Store

As the storage time of lithium-ion batteries increases, the batteries get older and their internal resistance increases. The internal resistance varies with different types of lithium batteries. After a long period of storage in September and October, the internal resistance increase rate of LFP batteries was higher than that of NCA and NCM batteries. The increase rate of internal resistance is related to storage time, storage temperature, and storage SOC.

4. Cycle

Regardless of storage or circulation, the influence of temperature on the internal resistance of the battery is consistent. The higher the circulation temperature, the greater the increase rate of internal resistance. The influence of different cycle intervals on the internal resistance of the battery is also different. The internal resistance of the battery accelerates with the increase of the depth of charge and discharge, and the increase of the internal resistance is proportional to the strengthening of the depth of charge and discharge. In addition to the influence of the depth of charge and discharge in the cycle, the charging cut-off voltage also has an influence: too low or too high upper limit of the charging voltage will increase the interface impedance of the electrode; too low upper limit of the charging voltage will not be able to form passivation film well; while too high upper limit of the voltage will lead to the oxidation decomposition of electrolyte on the surface of LiFePO4 electrode to form products with low conductivity.

5. Others

The on-board lithium battery will inevitably experience poor road conditions in the practical application, but it is found that the vibration environment has little influence on the internal resistance of lithium battery in the application process.

prospect

Internal resistance is an important parameter to measure the power performance of lithium ions and evaluate the battery life. The greater the internal resistance, the worse the multiplier performance of the battery, and the faster the increase in storage and recycling. The internal resistance is related to the structure of the battery, the characteristics of the battery material and the manufacturing process, and changes with the change of the ambient temperature and state of charge. Therefore, the development of batteries with low internal resistance is the key to improve the power performance of batteries. At the same time, it is of great practical significance to master the variation law of battery internal resistance for the prediction of battery life.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat