This coin cell crimper is mainly used in the laboratory button battery CR20XX series coin cell cases crimping, it can also be used for small batch trial production in factories.

Hydraulic coin cell Crimper Crimping Machine for Sealing Button Batteries Cases

Warning: Do not vacuum the sealer. (If you put it inside the glove box, the antechamber cannot be vacuum to prevent the oil is spilled.)

Model:AS-HCM-20

Product Introduction:

1. It is mainly used in the laboratory button battery and capacitor materials R&D, for CR20XX series coin cell cases crimping, it can also be used for small batch trial production in factories.

2. Equipped with different molds can be used for battery disassembly, battery electrode pressing, battery powder material tablet making and other operations.

Main Feature:

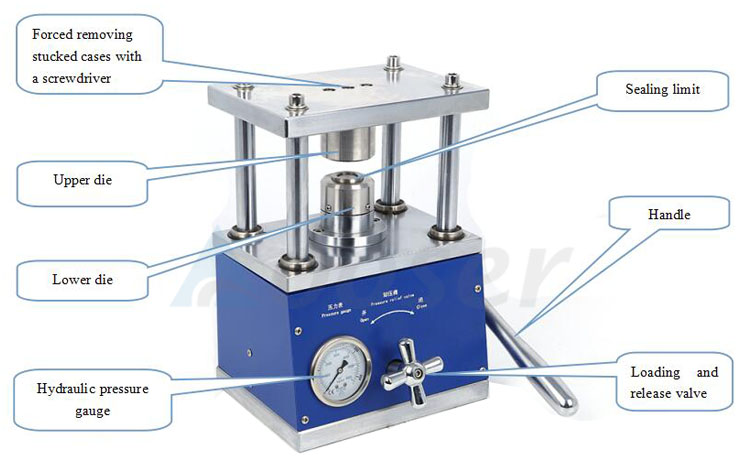

1. The lower die adopts a high-precision positioning ring limit to control the height of the sealed battery , It is for avoiding the damage of battery and crimping die when the pressure is unstable.

2. The inner cup of the upper mold is provided with a spring mechanism, for ensuring that the battery can be removed when the battery stucked during the crimping, the operation process is pressing the spring mechianism on the top side with a screwdriver.

3. Built-in safety overflow valve, the pressure can be adjusted as needed, and the limited upper pressure can be set to prevent damage caused by excessive pressure (caused by wrong operation), thus ensuring the safe use of the machine.

4. The built-in pressure gauge can observe and accurately control the sealing pressure.

5. It is hydraulic type with a pressure of up to 8T. The battery crimping has no vibration and no leakage.

6. Specially designed hydraulic structure for saving labor.

7. The precise mold design ensures accurate and reliable crimping performance, the solid steel structure design, which is stable and safe to use.

8. Small size, easy to operate, can be placed in the glove box.

9. Beautiful appearance, easy maintenance, compact size, easy operation, precise mold, etc.

Technical Parameters:

|

Model |

Manual Coin Cell Crimper AS-HCM-20 |

|

Appication |

Mainly for coin cell lab research |

|

Crimping Die |

1 One set of crimping die for CR20xx series coin cell cases, include CR2032,CR2025,and CR2016 2 Optional die available for crimping CR2325,CR2450,AG3,AG5 3 PTFE Anti-Corrosion Core prevents coin cells from being short circuited |

|

Advantages |

The lower die with high precision positioning ring spacing, control the battery package height. The upper die is provided with a sealing cup inner screw spring mechanism,ensure in case the battery sealing clamp can not be removed,only the top screw clockwise and the button battery out. 3 By using aluminum alloy and high strength steel, surface after the environmental protection electroplating processing will never rust. |

|

Handle Pressure |

<5.5kg |

|

Max Pressure |

200kg/cm2 |

|

Working Pressure |

80-100kg/cm2 |

|

Dimension(L*W*H) |

235mm*170mm*330mm |

|

Weight |

27kg |

|

Shipping Weight |

About35kg |

|

Warranty |

One Year limited warranty with lifetime support |

|

Service |

Oversea after-sales service is available |

Maintenance methods and precautions:

1. Wipe the dirt on the guide pillar and other moving parts frequently, keep it clean, and lubricate it to keep it moving smoothly.

2. When the machine is not used, keep oil valve loosened to return the moving template(lower die) to the initial position. If the machine do not need to use for a long time, take out the upper die and clean it, then apply oil to keep surface clean and smooth.

3. Regularly check the screws, nuts, pins and other fasteners on all parts of the machine to prevent looseness, and prevent the quality accidents and personal accidents.

4. During the operation, it is strictly forbidden to put the hand and other body parts to the dangerous place of the guide pillar, slide plate and working area. Two or more people are not allowed to operate it together to avoid accidental injury.

Solutions for common problems:

* The pressure is released during the crimping process or the pressure can not reached to the set value.

1. The oil pipe joint components are loosen. Inspect and tighten it.

2. Check the seal ring inside the joint. If the ring is damaged, then replace it.

3. The hydraulic oil in the jack is lacking. Open the rear cover, keep crimping machine side-lay, take out the cover of fuel filler, and fill with clean hydraulic pressure oil.

4. The safety relief valve has a low pressure setting. Set it with higher value.

* The button battery has a flaw on the side of the cases.

1. There is dirt on the molding surface of the crimping die. Wipe it and the oiling to keep the molding surface smooth.

2. The crimping die surface is damaged. Polishing the die or replace it.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat