The side voltage of lithium battery refers to the voltage between the positive lug of soft pack battery and the aluminum-plastic film.

In theory, the aluminum layer between the positive electrode and the aluminum plastic film is insulated, that is, their voltage should be 0.

In fact, during the processing of aluminum-plastic film, the inner PP layer will be locally damaged, resulting in local conduction (including electronic channels and ion channels) between them, forming micro cells, and thus the potential difference (voltage).

The side voltage standard varies from manufacturer to manufacturer, but most of the industry is set below 1.0V, the voltage standard is based on the dissolution potential of aluminum lithium alloy!

Why control side voltage?

Because if the inner PP film of the aluminum plastic film is damaged, the capacity will be corroded.

Corrosion conditions must have two points: 1, the electronic path, the negative electrode and the aluminum layer of the aluminum plastic film form the electronic path; 2, the ion path, the aluminum layer of the aluminum plastic film and the electrolyte form the ion path; In the absence of either, corrosion is not valid.

After the two conditions are established, the lithium ion will react with the aluminum layer of the aluminum plastic film to produce lithium aluminum alloy; Lithium aluminum alloy is a kind of powder material, resulting in the penetration of aluminum plastic film; That is, we often see some black spots inside the aluminum plastic film; These spots will become more visible over time and with the number of charges and discharges.

How to choose?

Currently, statistical detection methods are as follows:

1, test the resistance between the aluminum plastic film and the negative tab, more than 5M ohm is relatively safe, some companies define the relatively low, see you endure the final PPm of defective products, you can measure some data and then define their own standards can also; This resistance test is about picking out the electron path;

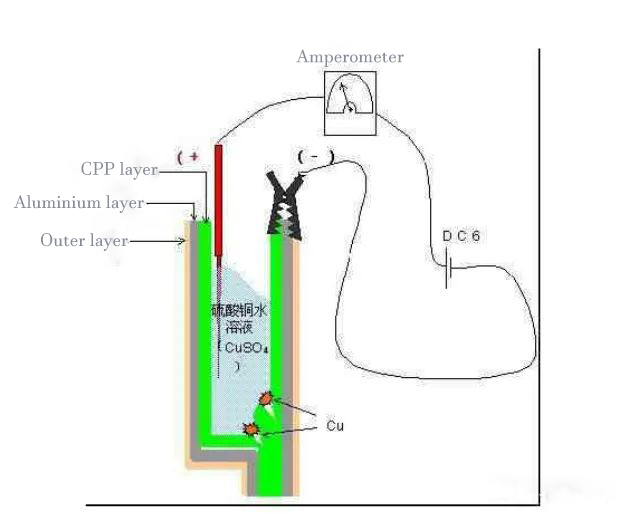

2, Test between the positive electrode and the current of aluminum film, can be tested with DC source, generally believed that the current is greater than 0.001mA, is defective products, need to be picked out;

3. Test the voltage between the positive electrode and the aluminum film, which is generally considered to be greater than 1V for defective products.

You can test 1 and 2, or 1 and 3 together.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat