In the next few years, the market will produce a large number of dead power batteries. In recent years, with the rise of a new round of energy revolution, many countries including China, Europe, the United States, Japan and South Korea have begun to vigorously develop new energy powered vehicles. According to Frost Sullivan's data, the global penetration rate of new energy passenger vehicles increased from 1.6% in 2017 to 9.7% in 2021. It is expected to reach 14.4% in 2022, and the penetration rate of new energy vehicles in China will increase from 2.7% in 2017 to 13.4% in 2021 and 24.0% in 2022, with a large number of power batteries entering the consumer end. On the other hand, the current power battery life is about 5-8 years. With the early new energy vehicles entering the scrap period, it can be predicted that the number of scrapped batteries will increase significantly in the next few years. Discarded power batteries contain a large number of valuable metals, which will not only cause a great waste of cobalt, nickel, manganese, lithium and other resources, but also seriously pollute the environment.

Power battery recycling will effectively reduce environmental hazards. Waste power batteries contain cobalt, lithium, manganese, nickel and other heavy metals and harmful substances. If not properly recycled, it will cause significant harm to the environment. For example, common cathode materials such as lithium cobalt, lithium manganese, lithium nickel, and lithium iron phosphate will form metal oxides with water, acid or oxidant, or cause heavy metal pollution. It will help reduce carbon emissions and achieve the goal of "double carbon". At present, the calculation of the carbon footprint of power batteries adopts the whole life cycle method. The recycling of waste power batteries can reduce carbon emissions. For example, BMW and Huyou Cycle will cooperate to disassemble power batteries, and through Huyou Cycle's advanced green metallurgy technology, extract core raw materials such as nickel, cobalt and lithium in a high percentage of batteries, and return 100% to BMW's own supply chain system and use them again in the production and manufacturing of power batteries for BMW new energy models. This will reduce carbon emissions from mining by 70%, significantly reducing the life-cycle carbon footprint of power batteries.

The price of nickel, cobalt, lithium and other valuable metals in power batteries is high. Take waste ternary lithium batteries as an example. Ternary batteries contain valuable metals such as nickel, cobalt, manganese and lithium. With the rapid growth of power pool output, the demand for materials containing these metals will continue to rise, making supply and demand even more tense. As of November 30, 2022, the prices of battery grade nickel sulfate, battery grade cobalt sulfate, battery grade manganese sulfate and battery grade lithium carbonate are 40,800 yuan/ton, 5800 yuan/ton, 60,600 yuan/ton and 568,000 yuan/ton, respectively. If it can be properly recycled, the waste power battery will release great economic value and become a veritable "city mine".

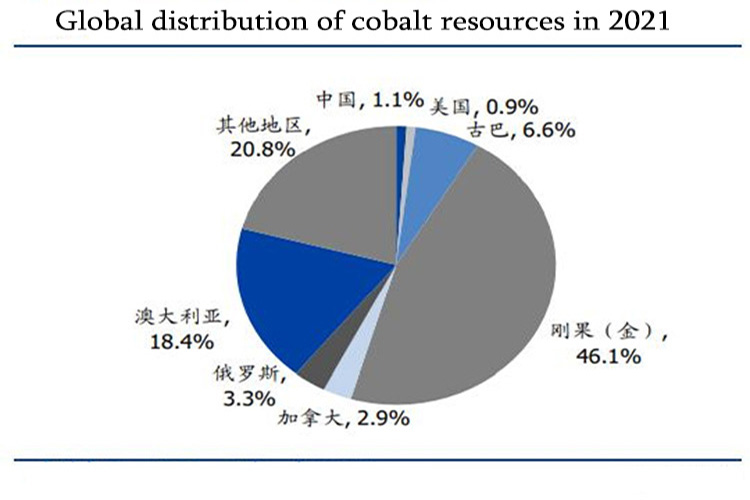

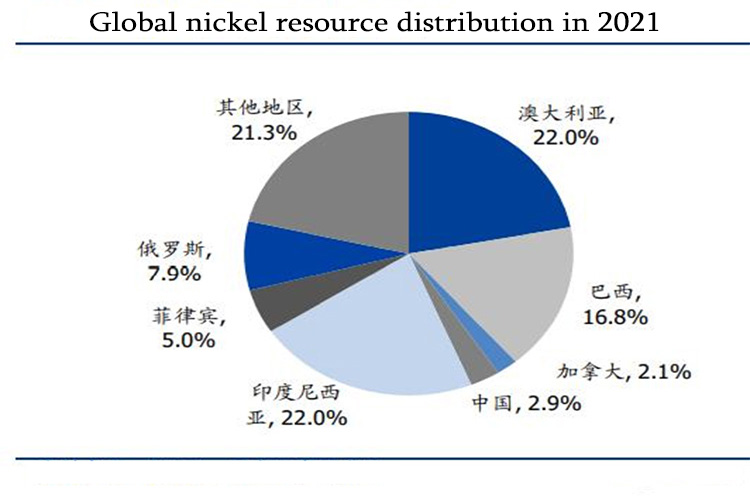

Reducing Resource Scarcity and External Dependence Experts from China Electronics Information Industry Development Research Institute and Solid Waste and Chemical Management Technology Center of Ministry of Ecology and Environment have calculated the scarcity of major resources needed for power lithium batteries, including the following four indicators: 1) proportion of consumption. It refers to the proportion of the consumption of a certain resource used in the production of lithium power batteries in the whole society. If the proportion exceeds 5%, the evaluation result is considered as large, and vice versa. 2) Account for the proportion of new consumption. It refers to the proportion of the new consumption of a certain resource used for the production of lithium power batteries in the whole society in 2025. If the proportion exceeds 10%, the evaluation result is considered to be large, and vice versa. 3) Whether it is easy to replace. To assess the likelihood of a resource being replaced or reduced in lithium battery production by 2025. 4) Whether it belongs to the 24 strategic minerals in China. According to the National Mineral Resources Plan (2016-2020), 24 kinds of strategic mineral resources are listed. Lithium, nickel and cobalt are finally determined as the three key materials with high resource security risk.

The power battery recovery mode can be divided into step utilization and regenerative utilization. Generally speaking, if the retired power battery still has the use value in other areas, it can be used in steps first. If it is not suitable or no longer meets the conditions of step utilization, it can be used in the link of reuse. For safety reasons, lithium iron phosphate batteries are generally considered to be more suitable for secondary utilization than lithium ternary batteries. In June 2022, the National Energy Administration issued 25 Key Requirements for Preventing Accidents in Electric Power Production (2022 version) (Draft for Comments), which proposed that ternary lithium batteries and sodium-sulfur batteries should not be used in medium - and large-sized electrochemical energy storage power stations, and step power batteries should not be used. At present, step-use accounts for about 14% of the total amount of batteries recycled, and the remaining 86% of batteries are directly recycled.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat