Model: AS-STX-04

Voltage: AC 220V 50Hz

Material: Stainless steel

Purification system: Yes

Regeneration: Yes

water and oxygen index: less than 1 ppm.

Aooser Brand Stainless Steel Vacuum Glove Box for Laboratory Battery Rearch

Brief Introduction:

This glove box(with four gloves) is a double station, single-sided operation, integrated with single-column purification unit, PLC control and touch screen operation, vacuum pump, bracket, a closed cabinet with tilting operating surface and detachable safety glass front window. Under standard conditions , that is, 20 degree centigrade constant temperature, a standard atmospheric pressure, 99.999% inert gas source, water and oxygen index is less than 1 ppm.

Features:

Closed Loop Gas Circulation

Inert gas in a closed loop. The gas is circulated by the blower and purifier, H2O, O2 can be removed continuously.

Automatic Purging

The replacement of the atmosphere inside the glove box can be achieved automatically by the purging valves.

Automatic Regeneration

H2O and O2 removal material can be regenerated. The regeneration process can be program controlled.

Automatic Pressure Control

The pressure in the glove box is controlled automatically by the Programmable Logic Controller (PLC). Working pressure can be set between +10mba and -10mba. If the pressure goes over+/- 12mbar, the system will be protected automatically.

Eco Mode

The vacuum pump will be activated automatically when necessary, and will turn off after a period of idle time. Blower frequency will be switched to 25Hz when moisture and oxygen level reaches to less than 1 ppm

Technology parameters:

|

Item |

Parameter |

|

|

Voltage |

AC 220V Single phase 50Hz, 110V optional |

|

|

Glove box |

Box |

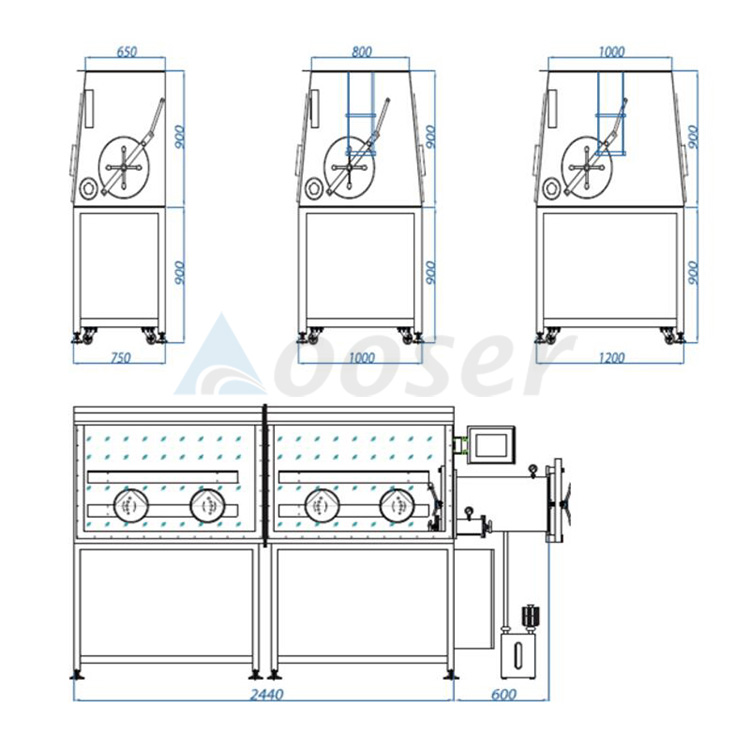

Box inner size: (L*W*H)=2440×750×900mm Box material: stainless steel 304, thickness 3mm Inner surface: stainless steel wire drawing treatment Outside surface: paint, white |

|

Front window |

Tilt windows, transparent tempered safety glass, thickness 8 mm |

|

|

Glove ports |

The material is polyoxymethylene, O-ring seal, self-lubricating performance, easy to maintain, and good sealing performance |

|

|

Gloves |

Butyl rubber, diameter 8", length 32" |

|

|

Filter: |

0.3 microns, a gas inlet and a gas outlet |

|

|

Shelf |

Stainless steel, 2 layers |

|

|

Lighting |

LED lights, installed in front of each glass window |

|

|

Connector |

Standby interface7pcs, DN 40 KF, Power interface 1pc (220V) |

|

|

Bigger transitive cabin |

Chamber |

Size: diameter 360mm, length 600mm Material: 304 stainless steel Surface: inner surfacewire drawing process, outer surface painting (white) |

|

Accessary |

Sliding tray: 304 stainless steel Door: double door, anodized aluminum material, thickness 10mm, vertical operation, with lifting mechanism Pressure gauge: Analog display |

|

|

Control |

Solenoid valve touch screen automatic operation |

|

|

Smaller transitive cabin |

Chamber |

Size: diameter 150mm, length 300mm (100mm lengthinto the glove box) Material: 304 stainless steel Surface: inner: wire drawing process, outer: painting (white) |

|

Accessary |

Door: double door, button press Pressure gauge: analog display Small compartment tray: 304 stainless steel |

|

|

Control |

Manual valve manual operation |

|

|

Gas purification circulation system |

Purification column |

Function: gassealed, remove water, remove oxygen Container material: 304 stainless steel Purification materials: copper catalyst: 5kg, molecular sieve: 5 kg Purification capacity: oxygen: 60L, water: 2Kg Water and oxygen indicators: less than 1ppm |

|

Circulatory system |

Working gas: nitrogen, argon Recycling capacity: integrated fan flow 90m³ / h, install frequency conversion |

|

|

Regeneration |

Operation: PLC automatically controls the regeneration process Regeneration gas: working gas mixed with hydrogen gas, (hydrogen 5-10%) |

|

|

Vacuum pump |

8m³ / h, rotary vane pump, with oil mist filter, air vibration control |

|

|

Valves |

Main valve: DN 40 KF, electrically operated angle valve Control valve:electromagnetic integrated valve (stainless steel integrated valvebase, single column for the six valve integration) |

|

|

Control System |

Function |

Including self-diagnosis, power-off self-starting characteristics, with pressure control and adaptive function Automatic control, cycle control, password protection, unit control using Siemens PLC touch screen |

|

Pressure control |

Control box, transition chamber pressure,the working pressure of the cabinet can be set freely within +/- 10mbar, and the system automatically protects beyond +/- 12mbar. |

|

|

Pedal |

Control the box pressure, easy to operate boost and buck |

|

|

Display system |

Using Siemens PLC touch screen, display running status, box pressure, system records etc |

|

|

Vacuum system control |

Vacuum pump, can be manually or through the PLC to start, flow 8m³/h,vacuum of the transitionchamber, and keep the box pressure balance, vacuum pump limit vacuum ≤ 2x10-1pa |

|

|

Warranty |

1 Year limited with lifetime technical support |

|

|

Packing weight |

About 600 Kg |

|

|

Lead time |

20-30 days |

|

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat