VGB-6 is a dual stainless steel glove box designed for researchers in material science, chemistry, semiconductor, and related topics. The purification cylinder is made of BASF antioxidant materials from Germany and UOP water adsorbent materials from the US in order to achieve a low water and oxygen concentration of lower than 1ppm, such that experiments can be conducted in an ultra clean and highly purified gas environment. It is integrated with vapor pressure control system, purity control system, automatic gas purity regeneration control system, auto alarm, and system data log recording.

Single Or Dual Chamber Vacuum Glove Box with Dry Gas Station Purification System

Description:

VGB-6 is a dual stainless steel glove box designed for researchers in material science, chemistry, semiconductor, and related topics. The purification cylinder is made of BASF antioxidant materials from Germany and UOP water adsorbent materials from the US in order to achieve a low water and oxygen concentration of lower than 1ppm, such that experiments can be conducted in an ultra clean and highly purified gas environment. It is integrated with vapor pressure control system, purity control system, automatic gas purity regeneration control system, auto alarm, and system data log recording.

Specifications:

|

Working Voltage |

220V AC, 50/60Hz, Single Phase |

|

Max. Power Consumption |

3KW |

|

Glove Box Chamber |

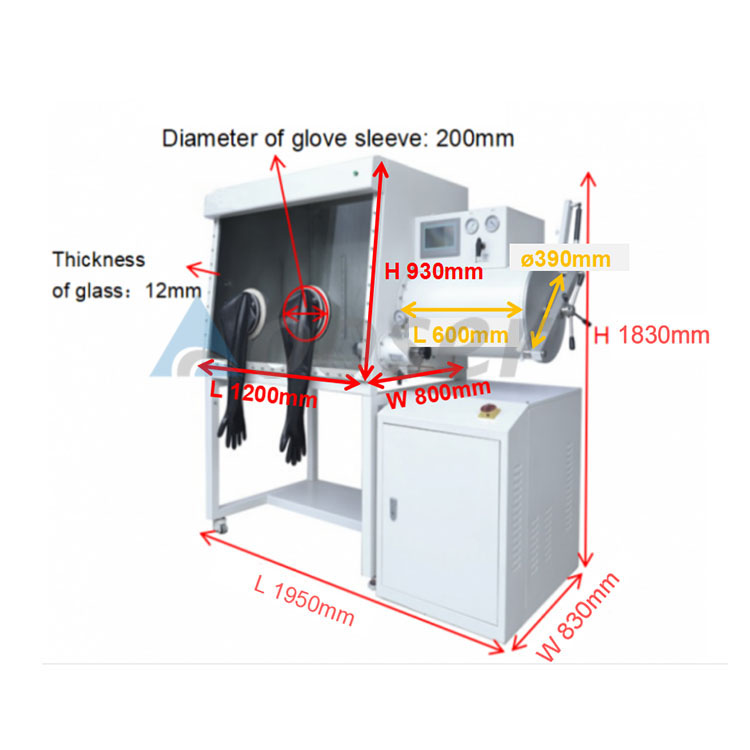

· Case Material: Stainless Steel 304 · Dimensions: 2400mm(L) x 800mm(W) x 930mm(H) · 12mm thick double layer laminated safety glass with corrosion protection film for operating in a safe and easy manner |

|

|

· Water concentration: <1 ppm (20°C, 1 atm) · Oxygen concentration: <1 ppm (20°C, 1 atm) |

|

Leak rate |

<0.05 Vol% / hr (Depending on oxygen concentration inside the glove box) |

|

|

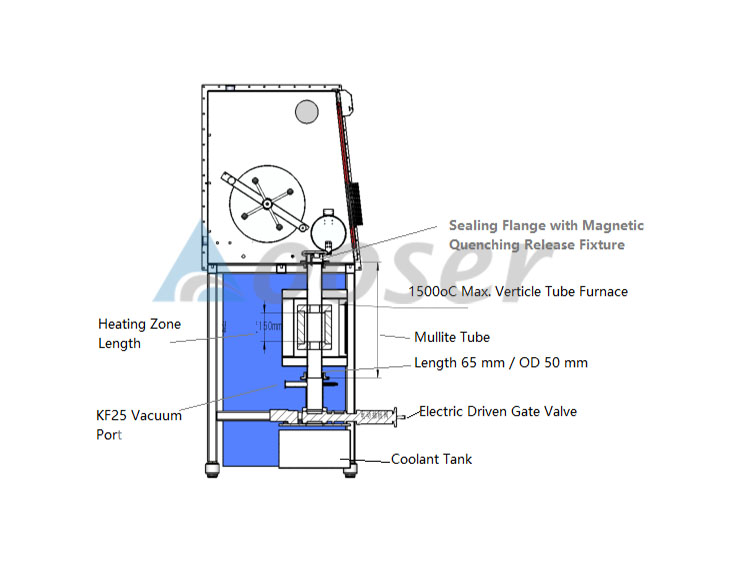

· Antechamber Dimensions: 385mm(Dia.) x 588mm(L) · Small Chamber Dimensions (for tools): 150mm(Dia.) x 300mm(L) · Max. vacuum level: 100 Pa |

|

|

· Operating gas: Inert gas such as N2, Ar, He · Regenerating gas: Mixture of H2 (10%) and Operating gas o For purification system with only water adsorbing function, Regenerating gas will be the same as Operating gas |

|

|

· Automated Regeneration Process · Automated water and oxygen removal · Purification Cylinder: made of BASF antioxidant materials and UOP water adsorbent materials · Moisture removal capacity: 1.5KG · Oxygen removal capacity: 180L |

|

|

· Organic Solvent Filter System filled with replaceable activated carbon · Built in HEPA filter can eliminate particle size > 0.3μm |

|

Control system |

· Siemens PLC control system with 6" touch screen display o Water concentration: 0 - 1000 ppm with an accuracy of 0.1 ppm o Oxygen concentration: 0 - 1000 ppm with an accuracy of 0.1 ppm o Pressure: -2500 to 2500 Pa with an accuracy of 1 Pa |

|

|

· England EDWARDS pump is included for faster vacuum and removing moisture · Vacuum rate: 8.4 - 12 m^3/hr |

|

Blower |

Flow Rate: 90m³/h |

|

Purification Pipeline |

304 Stainless Steel, KF40 Port |

|

Gloves |

A pair of NORTH butyl glove is included to provide better protection against toxic materials |

|

Lighting |

Built in fluorescent lamp |

|

|

· Three slidable shelves are built 0n top of inside glove chamber with dimensions of 300mm x 250mm · 300mm away from roof |

|

Product Dimensions |

3115mm(L) x 830mm(W) x 1830mm(H) (123" x 33" x 72") |

|

Shipping Dimensions & Weight |

Total 2 pallets #1: 86"x41"x84" #2: 86"x41"x83" Total weight 1800 lb |

|

|

· One Year limited warranty with lifetime support · Rusting and damage due to improper storage condition or maintenance is not covered by warranty · Gloves are consumable items and are not covered under warranty |

|

Application Notes |

· The channel between the glove box chamber and the gas purification system must be unimpeded during the operation of gas purifying · Always check the joints, gloves, sealing elements, and pipelines for air-tightness before and during the operation · Corrosive gases are prohibited as they will damage the water sensor and oxygen sensor · The inlet and outlet of the Air-lock Chamber must not be opened at the same time to prevent contamination by the external gas · Coolant water outlet must remain switched on all the time · System check frequently to replace filters and solvent adsorbents for maintanence and maximum efficiency |

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat