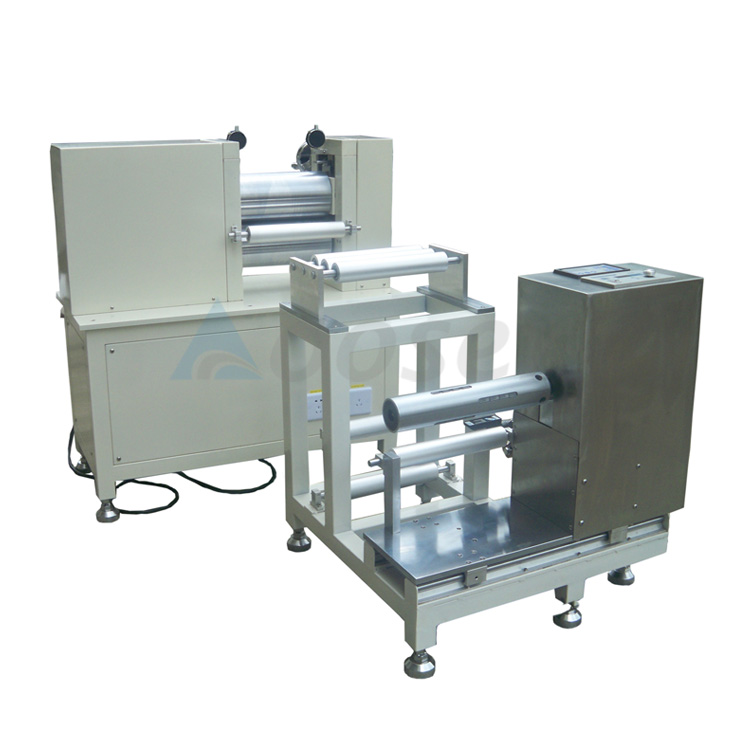

This Roll Press Machine is a continuous roll to roll heat calendering machine . It has dual rollers of 150mm dia. x 300mm width and dual micrometer. The roll press machine is an ideal hot rolling press for adjusting thickness and increasing active material density of the electrode in Li-Ion batteries research after coating and drying.

Model: AS-GYJ-1530

Rolling width: Max 300mm

Origin: China

Warranty: 18 Months

Heat Roller Press Machine For Lithium Battery Electrode Sheet Calendering With Winding And Unwinding System

Description:

1.This Roll Press Machine is a continuous roll to roll heat calendering machine . It has dual rollers of 150mm dia. x 300mm width and dual micrometer. The roll press machine is an ideal hot rolling press for adjusting thickness and increasing active material density of the electrode in Li-Ion batteries research after coating and drying.

2. This electric calender machine is mainly used for small electrodes in the rolling process, suitable for use by universities and enterprises experiment line, make the battery electrode compression molding, increased density.

3. It has a pair of 300mm width steel rollers. Such a roller can be heated up to 120℃.

4. The roll to roll system is withdeviation correction tension to controlwinding and unwinding.

Parameters:

|

Model |

Heat Roller Press with Winding and Unwinding System AS-GYJ-1530 |

|

Working Voltage |

3phase 380v 50hz, or 3phase 208v 60hz |

|

Power |

About 6000W |

|

Roller Dimension |

150mm(Dia.) x 300mm(W) (customized size is available) |

|

Roller surface hardness |

>HRC62 |

|

Rolling press accuracy |

≤±0.005 |

|

Roller surface finish |

0.8 |

|

Roller surface hardening depth |

5mm |

|

Rolling press thickness |

0-3mm adjusted with Dial gauge |

|

Rolling press width |

Max 300mm, Customized |

|

Rolling press speed |

0-6.5m/min adjustable |

|

Heating temperature |

RT-120℃, |

|

Application Notes |

This roller is specially designed for battery R&D in terms of its advantages as affordable, compact and precise. 1 Must use acetone to clean and dry rollers' surfaces after each use to avoid rusting 2 Coated Rust-proof oil if machine were to be unused for a long period of time 3 The minimum thickness of the rolled sheet should depend on the physical property of the materials. |

|

Package weight |

400kg |

|

Package volume |

0.7M3 |

|

Roll to Roll System for Hot Press Machine |

|

|

Electrode parameters |

Roller diameter : φ76 mm Reel and unreel max diameter : φ450 mm Electrode max width : 180mm |

|

Unreel and Reel parameters |

Accuracy : 5% Tension adjustment : 0.5~2.5Kgf |

|

Deviation correction |

≤±0.5mm |

|

Tension adjustment |

25N |

|

Dimension for Unreel |

About 70*45*85cm |

|

Dimension for Reel |

About 70*70*80cm |

|

Warranty |

18 Months from MFG date |

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat